Description

SH100/40060/0/0/00/00/12/11/00 Motor parameter settings

SH100/40060/0/0/00/00/12/11/00 Motor parameter settings

Module Clips Drive controller servo moto

SH100/40060/0/0/00/00/12/11/00A motor is a device that converts electrical energy into mechanical energy. SH100/40060/0/0/00/00/12/11/00 It utilizes an energized coil (i.e. stator winding) to generate a rotating

magnetic field and act on the rotor (such as a squirrel cage closed aluminum frame) to form a magneto electric rotational torque. Electric motors are divided into DC

motors and AC motors according to the different power sources used. Most of the motors in the power system are AC motors, SH100/40060/0/0/00/00/12/11/00 which can be synchronous motors or

asynchronous motors (the stator magnetic field speed of the motor does not maintain synchronous speed with the rotor rotation speed). An electric motor is mainly

composed of a stator and a rotor, SH100/40060/0/0/00/00/12/11/00 and the direction of the force acting on the energized wire in the magnetic field is related to the direction of the current and the direction

of the magnetic induction line (magnetic field direction). SH100/40060/0/0/00/00/12/11/00 The working principle of an electric motor is that the magnetic field exerts a force on the current, causing the motor to rotate.

Contact: Mr. Lai

Wechat:17750010683

Whats app:+86 17750010683

Skype:+86 17750010683

QQ: 3221366881

3221366881@qq.com

The mine hoist is an important transportation equipment for mining enterprises. Its main function is to transport the ore, personnel or equipment that need to be transported to the destination by the lifting container. Therefore, it plays a very important role in the mining production process. Usually the mine hoist control system consists of a driving part and a control part. The working mechanism of the driving part is: the motor unit drives the mechanical hoisting device, and the frequency converter or other types of hoisting control systems drive the motor unit: the working mechanism of the control part is: Each component of the hoist is coordinated and controlled by the Distributed Control System (DCS). In addition to completing basic process control, it can also integrate intelligent instruments, intelligent transmission and motor control, and even production management and safety systems into one operation and engineering environment. middle. Therefore, the mine hoist requires a control system with high performance, high reliability, and high integration.

1ABB800xA system and AC800M controller introduction

1.1ABB800xA system introduction

The 800xA system is an industrial information control system launched by ABB. The core of its architecture is object-oriented (ObjectOriented) technology. Due to the adoption of ABB’s unique Aspect0object concept, enterprise-level information access, object navigation and access can become standardized and simple.

In order to provide a unified information platform for enterprise managers and technical personnel, the 800xA system provides a base platform (BasePlatform), which relatively separates the process control part and production control management and organically combines them together. As shown in Figure 1, the middle part is the basic platform, the upper part is the production control management part, and the lower part is the process control part. The basic platform provides standard interfaces for these two parts for data exchange.

1.2 Introduction to ABBAC800M controller and its programming configuration tools

AC800M controller is ABB’s latest controller series, which includes a series of processors from PM851 to PM865. The AC800M controller itself has a pair of redundant TCP/IP interfaces. It can use the MMs protocol to communicate with other control devices and 800xA operator stations through Ethernet. It can also use the Modbus protocol and Point-Point protocol through 2 serial ports. communication. The programming and configuration tool of AC800M is ControlBuilderM, referred to as CBM. It supports standard ladder diagram, function block language, text description language and assembly language to write control logic.

2. Improve the design and implementation of control system functions

2.1 Implementation of elevator operating speed curve

One of the main tasks of the lifting control system is to control the lifting motor to operate according to the speed-position curve given by the design, so that the lifting container passes through the acceleration section, the uniform speed section and the deceleration section successively, and stops accurately after completing the specified lifting distance. somewhere in the wellbore. In order to realize the function of precise position calculation, the designed elevator control system must be able to perform high-precision position calculation based on the photoelectric encoder connected to the main shaft of the elevator drum. The calculation formula is as follows:

In the formula, s is the actual position value of the elevator: sp is the distance corresponding to two consecutive encoder pulses: AN is the difference between the encoder count value at the reference position and the current position (signed variable): s0 is the reference position value.

The encoder counts are distributed according to the circumference of the drum. After the number of pulses Np generated by the encoder rotation is known, the diameter of the circumference of the centerline of the wire rope wrapped around the drum must be accurately known, so that it can be calculated according to formula (2) The distance sp corresponding to the two encoder pulses:

In the formula, D is the circumferential diameter of the centerline of the wire rope: Np is the number of pulses for one revolution of the known encoder.

But in formula (2), there is a value D that keeps getting smaller as the system runs. This is because the wire rope used in the elevator is wrapped around the drum, and there is a lining between the wire rope and the drum that increases friction. This liner will become thinner and thinner as the system continues to wear and tear, causing the diameter of the circle formed by the center line of the steel wire rope to gradually become smaller. When the pad wears to a certain extent, it will cause a large position calculation error. In order to solve the above problems, the two parking position switches in the shaft are used to correct the drum diameter, because the distance between the two parking positions can be obtained through actual measurement with high accuracy. During the actual operation, record the encoder count values at the two parking positions respectively. According to formula (3), the actual correction value of sp can be calculated:

In the formula, sd is the distance between two parking positions: Abs is the absolute value operation: N is the encoder count value when there are two parking positions.

In this way, the initial sp value is first set according to the given design parameter value, and then the value is corrected according to the actual operating conditions, which can effectively ensure the accuracy of position calculation. At the same time, sp’ can also be substituted into formula (2), and the D value can be obtained in turn, which can be used as a basis for judging whether the liner is seriously worn.

After obtaining the elevator position value, the speed control curve can be calculated according to formula (4):

HE700GEN100C GE industrial control card

IC660ELB912J GE Genius Network interface module

FBM230 P0926GU FOXBORO Modbus main (serial and TCP/IP) driver

F8621A HIMA Central processing unit (CPU) module

ENT-10515-R HIRSCHMANN AC AC power module

DSAI130A 3BSE018292R1 ABB analog input module

DKC01.3-012-3-MGP-01VRS Rexroth DKC drives the controller

DIGIFAS-7202 KOLLMORGEN servo drive

DECS-200-2L BASLER ELECTRIC Digital automatic excitation regulator

CX1100-0001 BECKHOFF Power device and I/O port

CI520V1 3BSE012869R1 ABB AF100 communication interface

CC-PCNT02 HONEYWELL C300 module controller

A413654 METSO Communication module

BC25 ABB Robot card parts

A413240 METSO Printed circuit board

086329-004 ABB Control card

5466-316 WOODWARD analog input output module

1786-RPA Allen-Bradley ControlNet Modular repeater adapter

5204-DFNT-PDPMV1 PROSOFT Ethernet /IP to the PROFIBUS DPV1 main gateway

531X303MCPARG1 GE AC Power Supply board

810-017034-005 LAM VME PCBA, processor

8LSA25R0060D000-0 B&R Synchronous motor

64SD1-08KRF1-13 NAI Data multi-function board card

6SM77K-3.000 KOLLMORGEN Servo motor

6SM56-S-3000 KOLLMORGEN Servo drive

5PP320.1505-39 B&R Power panel PP320 BIOS15 “XGA color TFT display

3HAC9710-1 ABB Heat exchanger unit

YNT512D YOKOGAWA Trunk repeater

3BHB003688R0101 ABB Variable frequency circuit board

WR-D4007 RELIANCE Power supply card

VT-VSPD-1-23/V0/0-0-1 Rexroth magnifying plate

VE6041F01C1 DeltaV intelligent switch

UTLH21 TOSHIBA Industrial controller Unifi nv series controller

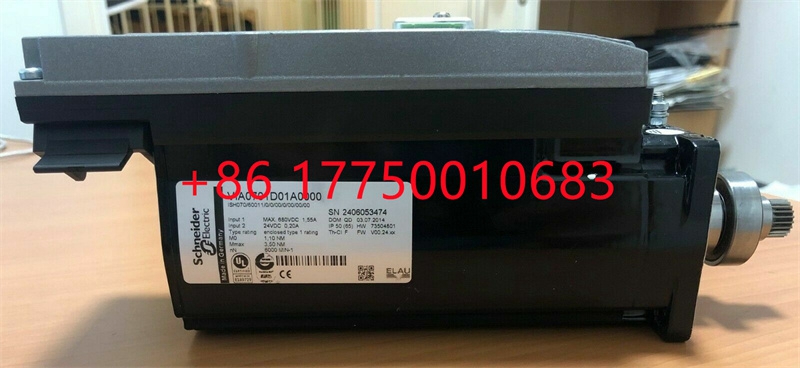

SM-100-40-080-P0-45-S1-B0 ELAU Servo motor

8310N2 TRICONEX 8310N2 Communication module

SC-TCMX01 51307198-175 HONEYWELL RTU2020 base

PW502 YOKOGAWA Isolated wide range power supply panel

SC-PCMX01 51307195-175 HONGEYWELL RTU2020 controller remote terminal device

PM865K01 3BSE031151R1 ABB AC800M Processor unit

PR9268/601-000 EPRO sensor

PFTL201C 3BSE007913R50 50KN ABB Pressure transducer

PCD232A101 3BHE022293R0101 ABB Controller processing unit

P4LQA HENF209736R0003 ABB Unit module

MP3010 EATON Fixed case motor protection relay

MDX61B0015-5A3-4-0T SEW Inverter drive

62K-NHC0-DH VIPA 10-inch ecological human-machine interface

MAX-4/11/03/128/99/1/1/00 Elau 24v Dc Pac Drive Control

LSH-050-2-45-320T1.1R Lust LTi Drives Servo motor

1.Has been engaged in industrial control industry for a long time, with a large number of inventories.

2.Industry leading, price advantage, quality assurance

3.Diversified models and products, and all kinds of rare and discontinued products

4.15 days free replacement for quality problems

ABB — AC 800M controller, Bailey, PM866 controller, IGCT silicon controlled 5SHY 3BHB01 3BHE00 3HNA00 DSQC series

BENTLY — 3500 system/proximitor, front and rear card, sensor, probe, cable 3500/20 3500/61 3500/05-01-02-00-001 3500/40M 176449-01 3500/22M 138607-01

Emerson — modbus card, power panel, controller, power supply, base, power module, switch 1C31,5X00, CE400, A6500-UM, SE3008,1B300,1X00,

EPRO — PR6423 PR6424 PR6425 PR6426 PR9376 PR9268 Data acquisition module, probe, speed sensor, vibration sensor

FOXBORO — FCP270 FCP280 FCM10EF FBM207 P0914TD CP40B FBI10E FBM02 FBM202 FBM207B P0400HE Thermal resistance input/output module, power module, communication module, cable, controller, switch

GE —- IS200/215/220/230/420 DS200/215 IC693/695/697/698 VMICPCI VMIVME 369-HI-R-M-0-0-E 469 module, air switch, I/O module, display, CPU module, power module, converter, CPU board, Ethernet module, integrated protection device, power module, gas turbine card

HIMA — F3 AIO 8/4 01 F3231 F8627X Z7116 F8621A 984862160 F3236 F6217 F7553 DI module, processor module, AI card, pulse encoder

Honeywell — Secure digital output card, program module, analog input card, CPU module, FIM card

MOOG — D136-001-007 Servo valve, controller, module

NI — SCXI-1100 PCI – PXIE – PCIE – SBRIO – CFP-AO-210 USB-6525 Information Acquisition Card, PXI Module, Card

Westinghouse — RTD thermal resistance input module, AI/AO/DI/DO module, power module, control module, base module

Woodward — 9907-164 5466-258 8200-1300 9907-149 9907-838 EASYGEN-3500-5/P2 8440-2145 Regulator, module, controller, governor

YOKOGAWA – Servo module, control cabinet node unit

Main products:

PLC, DCS, CPU module, communication module, input/output module (AI/AO/DI/DO), power module, silicon controlled module, terminal module, PXI module, servo drive, servo motor, industrial display screen, industrial keyboard, controller, encoder, regulator, sensor, I/O board, counting board, optical fiber interface board, acquisition card, gas turbine card, FIM card and other automatic spare parts